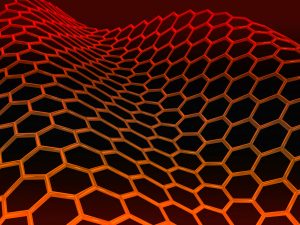

Graphene molecular structure © Ekaterina Shilova – stock.adobe.com

Graphene is a one-atom thick layer of carbon and is considered to be a new wonder molecule. Its production became possible only very recently and graphene is now available for various applications. The term graphene is often applied to many members of the family of graphene-based materials the two most important members being graphene and graphene oxide (GO). Graphene is transparent, flexible and very stable on a molecular level. Various future uses of graphene and graphene oxide are expected, from applications in the fields of electronics, photonics, composite materials, energy generation and storage, sensors, metrology to uses in biomedicine.

How can I come in contact with this material?

Currently, graphene is still an experimental material, which was first discovered in 2004. Therefore, there are only few products or applications on the market (e.g. a tennis racket). The most likely path currently for someone to get into contact is via inhalation (breathing in) of graphene nanoparticles or graphene oxide nanoparticles in a laboratory environment.

Is there any risk from this material to humans and the environment?

So far it is too early to conclude on positive or negative biological effects on humans, but first experiments with animals showed that lung damage can occur after inhalation of graphene nanoparticles. Concern has been raised by lung specialists about the safety of graphene and graphene oxide. They strongly recommend that appropriate inhalation (lung uptake) experiments of graphene must be undertaken in order to better understand the respiratory safety profile of this group of materials.

Conclusion

At present graphene and graphene oxide are still experimental materials and mainly important for research. The incidence of potential exposure to these materials is very small at this point in time, but it will be important to follow what the future for this material holds in terms of its human and environmental safety profile.

Properties and Applications

Graphene film © bonninturina / fotolia.com

The material graphene consists of pure carbon and is predicted to enable promising applications in nanotechnology. Therefore, the European Commission funds research on this "wonder" material with a total of up to 1 billion euros within its biggest ever EU-funded research project "Graphene flagship".

Strictly speaking, graphene is a one atom layer of pure carbon. It is one of several so-called (crystallographic) modifications of carbon. Two modifications show different properties, despite the same chemical composition, because the carbon atoms are arranged in a different way (see also Crystal Structures of Nanomaterials). In addition, a distinction must be made between monolayer graphene, graphene with a few layers (few-layer graphene), graphene with up to 10 layers and Graphene with a thickness above 10 layers, which is called graphite as described below.

The thickness of a graphene layer is approximately 0.3 nanometers and this value represents approximately a hundred thousandth of the thickness of a human scalp hair. The lateral spread of a layer most often usually is much greater. Each carbon atom in a graphene monolayer is chemically bonded to three other carbon atoms. This leads to a (two-dimensional) structure with honeycomb layering.

Tip of a pencil: Graphite is responsible for the gray color of pencil leads © WimL / fotolia.com

Graphene is closely related to graphite, which is a further modification of carbon and best known as ingredient of pencil lead. Graphite consists of many stacked carbon layers and therefore has a three-dimensional-layered structure. In addition to graphene and graphite, other modifications of carbon exist and include diamond and fullerenes. Graphene is also found as so-called amorphous carbon, e.g. in carbon black. The different graphene types have not been named precisely even in the technical literature. Thus, -depending on the context- the same name is used for different graphene types .

Graphene and graphite react well with oxygen to form so-called graphene oxide (GO). Graphene oxides can contain different amounts of bound oxygen. Such graphene oxides can react with other molecules or atoms, which is called functionalization. In practice, it is very difficult to distinguish graphene from graphene oxide and therefore, the term graphene-based materials (GBMs) is used to include various mixtures of graphene and graphene oxide .Graphene-based materials have outstanding properties in various ways .

Works as a flame retardant: mixed with plastics, multi-layer graphene is hard to inflame and expands upon heat treatment, thus it can act in this manner as thermal insulation.

Increases strength of polymers: Graphene can bear high mechanical loads and at the same time it is stretchable. With the highest-ever measured tensile strength of approximately 130 GPa (109 Pa), a monolayer of graphene, for the same mass, has a 25 to 250 times higher tensile strength tensile strength than steel .

Use in touchscreens: Thin sheets of graphene are optically transparent and electrically conductive and may be used in solar cells and touch screen displays as optically transparent electrodes. Broadly, this would be an alternative to the so far used but expensive materials such as silver and indium tin oxides (ITO).

Use in packaging, fuel tanks, tires, thermal insulation: The incorporation of Graphenes into plastics prevents that gases and liquids can penetrate them. This improves the shelf-life of foods or leads to cost-effective thermal insulation, which significantly improves the energy efficiency of buildings.

Applications in micro- and nanoelectronics: Single layer graphene has both, good heat conductance and electrical conductance. Therefore graphene may form the basis of new carbon based microprocessors which are significantly more powerful than silicon-based processors.

Applicatons in medical science: Future applications using functionalized graphenes could enable drug delivery through cell membranes, e.g. for cancer treatment. Furthermore, novel analysis techniques in medical applications may make use of graphene based materials.

In addition, a large number of other applications are planned , e.g., capacitors for energy storage, organic light-emitting diodes (OLEDs), batteries, catalysts or tailor-made agents.

For the end user there are not (yet) commercial products with graphene available on the market. However, it is expected that the abovementioned properties of graphene based materials will open up a variety of possibilities to develop novel products which show a highly improved efficiency or stem from more sustainable production processes.

Graphene is not self-inflammable. As a mixture with air (dust) under the influence of an ignition source, graphene can be possibly ignited (dust explosion). The behaviour in a dust explosion is similar to that of other, carbon-based materials.

Production

Andre Geim, Kostya Novoselov © U. Montan

Single-layer graphene was first isolated in 2004 by a group of physicists at the University of Manchester, under the direction of Andre Geim and Kostya Novoselov, and in 2010, the Nobel prize was awarded to them for their discovery .

So far, it has only been possible to produce graphene at laboratory scale or in small quantities. There are large efforts worldwide to develop processes for the mass-production of graphene. Depending on the scope of the intended application the fabrication process varies distinctively. Single-layer and few-layer graphene can be produced through either bottom-up methods or top-down exfoliation methods.

Using the top-down exfoliation method a single-layer of graphene is separated from a graphite crystal. This is done mostly mechanically by means of adhesive tape. A second way is the production of graphene from graphene oxide. This is done by the conversion of graphene oxide into graphene or few layer graphene using chemical or thermal means and by applying mechanical forces. This can be done in a liquid at an elevated temperature under strong stirring or ultrasonic treatment (i.e. sonic exfoliation). After chemical functionalization few-layer graphene, can be mixed with the starting materials of synthetic materials (for example plastics) for combined processing in subsequent steps.

An example of a bottom-up process for graphene production, uses a mixture of argon and methane gas, which is blown over a clean or coated metal surface (which functions as carrier or substrate). Through decay of the methane gas graphene is formed on the surface of the carrier. For the production of electrical components, the graphene layer is transferred from the first carrier to a second carrier. By further processing steps various electronic components can be manufactured eventually.

More detailed information on the production and processing methods for graphene based materials can be found in the literature .

The biological effect of graphene depends on its physicochemical properties. A coating plays a decisive role in determining its biological effect.

General Hazards

At the moment there is no information available about how or to which extend humans are exposed to graphene and graphene related materials. If graphene and graphene-related compounds are potentially toxic, is yet to be clarified.

In scientific literature the term graphene is often used for a variety of substances similar to graphene, but which are different to graphene regarding their physico-chemical properties and their biological activity. As a consequence, there are inconsistent statements published and disagreement exists about the biological effects of graphene. Graphene-related materials are available in multiple sizes, shapes and with different chemical modifications. For example, it is possible that a graphene-related material consists of only one layer (graphene) or of a multilayer-system like graphite. Also graphene-related materials can be produced by very different methods. The manufacturing method and the raw materials used as well as chemical and biological contaminants can equally influence the biological activity.

To what extend these different parameters influence the toxicological profile is the topic of current studies. For the specification of the toxicological profiles of graphene and graphene-related materials a standardized nomenclature and classification system is absolutely mandatory. One suggestion for such nomenclature has been given recently . Based on this design, concepts for the classification of graphene-related materials depending on their physico-chemical properties for biomedical applications and nanosafety-research were developed. In addition to graphene and its common graphene-related materials like graphite, graphene oxide and graphite oxide a variety of graphene-derivatives and other 2D-materials have been developed, whose biological activity is not known yet.

Studies on Living Organisms - in vivo

The respiratory tract is considered as the potentially main entrance route for graphene-related materials in humans. To date there are no studies available on the effect of these materials on humans.

A comparative inhalation study in rats showed, that the toxicity of carbon-based materials is depending on many parameters. Carbon Black and graphite nanoplatelets caused no negative effects after inhalation. In contrast, carbon nanotubes showed the most severe effects followed by graphene with less toxicity .

Inhalation of graphene platelets causes inflammation in the lungs of mice which decrease slightly one week after exposure. The smaller fragments are being removed due to the self-cleaning mechanisms of the lung .

In contrast, graphene oxides cause acute damage to the lungs of mice after instillation . The authors recommend for biomedical applications to sustain a stable dispersion of nanoscale graphene and to minimize contamination with graphene oxides.

Application of fluorescence-labelled graphene layers during tumour therapy in combination with photo-thermal therapy could result in shrinkage of the tumour without displaying any toxic side-effects .

Radioactive-labelled graphene layers can be detected in the livers and spleens of mice after injection but do not cause damage to organs or toxic side-effects. The noted side-effect of brown colouring of the liver and kidneys was found to gradually disappear within time .

Studies Outside of Organisms - in vitro

Several authors have emphasized the fact that carbon-containing particles may cause difficulties for the evaluation of experiments when used in cell culture test-systems . This is also true for graphene-related materials . Interactions of these particles with e.g. dyes can lead to false-positive and, thus, invalid results that do not allow statements on the toxicity of carbon-containing particles. Therefore it has been recommended to apply a second test method to verify the obtained results .

Like carbon nanotubes graphene-related materials are tested e.g. as candidates for the treatment of cancer. One key-requirement for such application is the compatibility with human blood. Liao and colleagues did detect a dose-dependent rupture or destruction of red blood cells. In contrast, graphene oxide that has been coated with chitosan prevents the destruction of red blood cells .

Furthermore, researchers could detect a loss of viability and the generation of reactive oxygen species (ROS) in human skin cells, in which the respective form of the material – graphene oxides or graphene layers – seemed to play a significant role: aggregated graphene layers are more toxic to the cells than reversibly aggregated graphene oxides.

In another recent study the authors report that lung cells treated with graphene oxide don't show any morphological changes or problems with adherence and growth. Additionally, no significant loss in viability, membrane damage or cell death such as apoptosis or necrosis are detectable. Transmission electron microscopy (TEM) analysis shows integrity of cellular structures and no graphene oxide can be detected within the cells. However, exposure to even low doses of graphene oxide induced oxidative stress. In another study graphene-nanoshells didn't cause morphological changes of cells. There was no toxicity detectable although the material generated oxidative stress, too. In addition the intracellular uptake of graphene-nanoshells by lung cells was observable in TEM-pictures .

One study shows dose-dependent membrane damage in macrophages by graphene-nanoplatelets, which trigger oxidative stress and the release of inflammatory markers .

Duch and colleagues couldn't find apoptosis in macrophages when they treated them with well-dispersed or aggregated graphene-materials. In contrast, they observed apoptosis when they incubated the same cells with larger graphene-layers .

Depending on the cell type, the type of graphene-related materials and the type of coating cellular stress, cell damage and even apoptosis can be induced (mainly through lipophilic coatings) whereas the cells remain vital even at the highest concentrations (in case of hydrophilic coatings).

Currently, there are no data regarding the environmental exposure of graphene.

Only a few studies with reliable results have been published on the inhalation of graphene. There are currently no known studies on absorption via the skin and the gastrointestinal tract.

Uptake via the Lung - Inhalation

Biological effects after inhalation of different carbon nanomaterials were investigated in mice . Besides well characterized materials like carbon nanotubes, carbon black and graphite, graphene was tested as a new 2D-material. Carbon nanotubes showed the highest biological effects, even though they were significantly less concentrated compared to the other materials tested. Also graphene induced biological responses, but to a lesser extent than carbon nanotubes. Carbon black and graphite showed no toxicity.

According to a study, inhalation of graphene platelets leads to inflammation in the lungs of mice which decrease slightly one week after exposure. The self-cleaning mechanisms of the lung deal with the removal of smaller fragments .

Studies with regard to potential ecotoxicological effects of graphene have been carried out mainly in bacteria, and comparing various surface modifications of graphene. Graphene mainly occurs in flake or film form with dimensions in the micrometer range. Findings on the effects of graphene appear to be very inconsistent, as it shows both, inhibitory and growth-promoting effects in bacteria.

Graphene as a nanomaterial is so in only one dimension (out of three), i.e. as nano-sheets or nano-films. In the biological tests graphene flakes are used.

The various graphene surface modifications have been shown to exhibit varying degrees of antibacterial activity, with smaller graphene platelets being significantly more toxic than larger ones and with different sensitivities for effects across bacterial species . The mechanism of effect for graphene is most likely to be damage to cell membranes by direct contact with the sharp-edges of graphene in its sheet form. Oxidative stress resulting from exposure to graphene has also been observed. In bacteria graphene has been shown to be toxic, but only at very high levels of exposure . Sludge bacteria show reduced viability after exposure to graphene, inhibiting their capacity to purify sewage . In contrast with these findings, there are also reports for improved growth of bacteria in the presence of graphene . In this case, material was thoroughly cleaned before experimental testing, possibly indicating that the toxic effects seen for other studies probably arise from impurities. Some types of bacteria are able to metabolize oxygen from functional groups of modified graphene surfaces, hence change their surface .

The various graphene surface modifications have been shown to exhibit varying degrees of antibacterial activity, with smaller graphene platelets being significantly more toxic than larger ones and with different sensitivities for effects across bacterial species . The mechanism of effect for graphene is most likely to be damage to cell membranes by direct contact with the sharp-edges of graphene in its sheet form. Oxidative stress resulting from exposure to graphene has also been observed. In bacteria graphene has been shown to be toxic, but only at very high levels of exposure . Sludge bacteria show reduced viability after exposure to graphene, inhibiting their capacity to purify sewage . In contrast with these findings, there are also reports for improved growth of bacteria in the presence of graphene . In this case, material was thoroughly cleaned before experimental testing, possibly indicating that the toxic effects seen for other studies probably arise from impurities. Some types of bacteria are able to metabolize oxygen from functional groups of modified graphene surfaces, hence change their surface .

Similar to effects observed in bacteria, the sharp-edged graphene can also cause irreversible cell wall damage in green algae .

Similar to effects observed in bacteria, the sharp-edged graphene can also cause irreversible cell wall damage in green algae .

Water fleas actively incorporate graphene nanomaterial by filtration of the surrounding water. The water flea however appears to be capable of excreting the graphene and no toxicity was observed . For Artemia (brine shrimps), graphene is also non-toxic but there are signs of oxidative stress. However, similar to water fleas it is taken up into the intestine .

Water fleas actively incorporate graphene nanomaterial by filtration of the surrounding water. The water flea however appears to be capable of excreting the graphene and no toxicity was observed . For Artemia (brine shrimps), graphene is also non-toxic but there are signs of oxidative stress. However, similar to water fleas it is taken up into the intestine .

Graphene flakes have been detected in the intestine and in freshly deposited eggs of C. elegans, a nematode . However, no toxicity based on mortality, reproduction or genetic changes was observed. When the worms were chronically exposed to graphene, however, both movements and oviposition were impaired. These observations have been attributed to oxidative stress .

Graphene flakes have been detected in the intestine and in freshly deposited eggs of C. elegans, a nematode . However, no toxicity based on mortality, reproduction or genetic changes was observed. When the worms were chronically exposed to graphene, however, both movements and oviposition were impaired. These observations have been attributed to oxidative stress .

Barnacles are sedentary organisms and hence they do no change their location in the adult state. Their larvae, however, are free swimming and graphene was shown to prevent the attachment process as the barnacle larvae settle on rocks to begin their adult life stage. In addition, the swimming behavior of the larvae is slowed down and there is a higher mortality rate .

Barnacles are sedentary organisms and hence they do no change their location in the adult state. Their larvae, however, are free swimming and graphene was shown to prevent the attachment process as the barnacle larvae settle on rocks to begin their adult life stage. In addition, the swimming behavior of the larvae is slowed down and there is a higher mortality rate .

One study examining the influence of differently modified graphene nanomaterial on the development of zebrafish.and some malformations were observed in graphene-exposed embryos, but in small numbers only. The survival rate was not affected. Another study showed similar effects of graphene on zebrafish embryos. There was no increase in mortality, but impairments of heartbeat, in the hatching rate and there was a reduced body size.

One study examining the influence of differently modified graphene nanomaterial on the development of zebrafish.and some malformations were observed in graphene-exposed embryos, but in small numbers only. The survival rate was not affected. Another study showed similar effects of graphene on zebrafish embryos. There was no increase in mortality, but impairments of heartbeat, in the hatching rate and there was a reduced body size.

Graphene nanomaterial has been shown to have inhibitory effects on the growth of plants, including tomato, cabbage and spinach seedlings but not for young lettuce plants . The exposure of plants with graphene triggered oxidative stress.

Graphene nanomaterial has been shown to have inhibitory effects on the growth of plants, including tomato, cabbage and spinach seedlings but not for young lettuce plants . The exposure of plants with graphene triggered oxidative stress.

In summary, according to most recently available studies graphene nanomaterials may be toxic to bacteria, but this is not an unanimous finding. In general, graphene was found to be non-toxic for most higher animals. An exception here is for barnacles, whose larvae were adversely affected by graphene exposure. Any non-physical effect of graphene on an organism was generally related to oxidative stress.

Studies with the aim of a biomedical application of graphene-related materials provide first insights into the distribution in the body. The uptake of different graphene-related materials could be demonstrated in different cell types.

Behaviour in the Body

Several graphene-related materials, particularly graphene oxide, are potential candidates for biomedical applications. It is planned e.g. that they reach specific target organs or cells via the blood stream as drug-carriers. Therefore it is no surprise that most in vivo studies investigate the intravenous administration of graphene-related materials and their distribution in the body. Bussy and colleagues stated that 64% of graphene-related materials were administered via this route . Additionally this study revealed that most of the materials described as graphene didn't fulfil the criteria.

Overall, an accumulation of the tested graphene-related materials was found in lung, liver and spleen. However, most of these materials showed no harmful effects. Nevertheless, more studies on this topic are urgently required.

Behaviour of uptake in somatic cells

Several studies have shown that graphene-related materials could be internalized by cells. But the underlying uptake mechanism is not fully understood. It can be assumed, that the uptake mechanism is highly depending on the material property and especially on the size distribution as well as on the respective cell type. In vitro experiments demonstrated e.g. the uptake of graphene nanoshells by lung epithelial cells .

Functionalized graphene can be used as so-called nanocarriers e.g., for drug transport in cancer therapy. Intention of this application is to facilitate the uptake of an active substance-loaded graphene into the target cells and thereby ensuring no toxic side-effects. Presumably uptake occurs via receptor-mediated endocytosis .

Schinwald and colleagues showed that due to the size of the respective graphene platelets (approximately 15 µm in diameter) uptake is incomplete which then leads to a so-called "frustrated phagocytosis meaning the cells suffocate on the platelets.

In contrast smaller platelets can be completely phagocytosed . Mouse macrophages displayed intracellular graphene in membrane-bound vesicles .

Besides also the type of coating decides on whether the graphene remains stuck on the surface of the cellular membrane as an aggregate or whether it is taken up into the cells .

There are only very few studies on the behaviour of graphene nanomaterials in the environment, focusing on surface-modified graphene. Graphene nanomaterials are highly mobile in soil and water bodies, and are able to bind other compounds.

Graphene nanomaterials are stable in surface waters and transport across long distances is feasible. Transport is independent of the waters' pH, whereas salts and ions were found to affect the transport of graphene. By binding to natural substances contained in waste waters, graphene nanomaterials are destabilised, leading to sedimentation into water bodies sediments .

In sandy soils, graphene nanomaterial transport is independent of soil pH. Due to their high binding capacity, graphene may bind other compounds and hence affect the spread of chemicals in the environment. One study demonstrated an increased mobility of graphene in soil subsequent to the sorption of other substances .

>

>