>

DaNa 4.0

>

DaNa 4.0

DaNa 4.0

DaNa4.0 – Data on new, innovative and safe application related materials

DaNa4.0 was a science communication project dealing with the safety of novel materials. The project dealt with questions whether certain materials could be harmful to humans and/or the environment or whether and how humans and the environment could come into contact with these materials.

A new, innovative material is interesting for the DaNa project if it is being worked on in research projects, is already included in a product or is mentioned in the press. Then we conduct an intensive literature search and evaluation with the help of our “Literature Criteria Checklist“.

Complex, toxicological questions from current materials research were prepared in a generally understandable way and presented in a way that is understandable for non-scientists (interested consumers, journalists, politicians, NGOs etc.). These topics are communicated via the website www.nanopartikel.info/www.nanoobjects.info, brochures and info flyers in an interdisciplinary approach with scientists from human toxicology, ecotoxicology, biology, physics and chemistry.

NanoINHAL

NanoINHAL – In-vitro test methods for airborne nanomaterials to investigate toxic potential and uptake after inhalation exposure using innovative organ-on-a-chip technology

Project report:

In this collaborative project, an innovative device-based method was developed to screen airborne (nano)materials for their toxic effects. For this purpose, an exposure unit was established to expose human alveolar lung models at the air-liquid interface to the materials. In parallel, an integrated microfluidic two-organ chip was developed that combines the human alveolar lung model with a human liver model and ensures long-term co-culture by continuous medium perfusion of the organ models. The functionality was demonstrated using biological parameters for the lung and liver. By combining the device and the two-organ chips, the prototype of an animal-free, compact NanoCube system for the assessment of human exposure to inhaled nanomaterials in the working environment was developed. The severe delays in the project schedule caused by the Corona pandemic were almost completely made up by a cost-neutral 9-month project extension. However, the final feasibility study could not be completed within this timeframe. The partners are currently searching for a suitable funding of this final step.

InnoMat.Life

InnoMat.Life – Innovative Materials and new production processes: Safety along the Life Cycle and in industrial value chains

Final report:

InnoMat.Life studied selected innovative materials during their life cycle and assessed material properties, release and exposure as well as potential hazards for humans and the environment. Three innovative material classes were selected: (nano-)fibres; polydisperse polymer particles for additive manufacturing and materials with complex composition and/ or morphology. InnoMat.Life build on existing knowledge primarily from nanosafety research and tested for instance the applicability/ transferability of existing test methods. To avoid testing each and every material variant individually, InnoMat.Life developed criteria catalogues to describe similarity to establish grouping approaches as an overall project goal. InnoMat.Life therefore delivered important contributions to the risk assessment of the selected innovative materials.

(1) (Nano-)fibres

The fibre principle describes a well characterised morphological principle according to which fibres with specific physico-chemical properties (so-called WHO-fibres) may cause severe human lung health hazards upon inhalation. Nanofibres are in particular challenging. Thin fibres are not stiff enough, can coil up and will not show a characteristic fibre mode-of-action. InnoMat.Life build on the existing knowledge from projects such as the BMBF-funded project nanoGRAVUR (Project ID 03XP0002) or the EU project GRACIOUS (Grant Agreement No 760840) but for the first time a much broader selection of fibres was investigated, including different nanofibers.

(2) Polydisperse polymer particles for additive manufacturing (3D printing)

Many polymers are considered biocompatible such that they can be grouped together following the OECD Polymers of Low Concern concept. The project assessed to which extent this concept could be transfered to polymer particles and which criteria would be needed. We focused on polymer particles for innovative applications, specifically additive manufacturing. InnoMat.Life for the first time systematically investigated a larger selection of different polymer particles, established several useful methods and thereby delivered an important contribution to the risk assessment.

(3) Materials with complex composition and/or morphology

For this material class our investigations focused on characterizing a potential impact of the morphology on the hazards. For this purpose selected materials in different forms were studied (e.g. titanium dioxide particles versus cubes versus fibres). However, only the fibre morphology showed a distinct effect. On the other hand different hybrid metal particles for additive manufacturing were investigated. No specific effects were detected. Based on the results and the investigated criteria an overarching grouping scheme for more complex materials was established.

-

- Detailed summary of InnoMat.Life project results (, 200 KB)

Project Website: www.innomatlife.de

InnoMat.Life Project Team (c) InnoMat.Life Project Consortium

CarboBreak

CarboBreak – Prerequisites and mechanisms for the release of alveolar fibrous carbon fibre fragments

Final report:

The BMBF project CarboBreak was a joint research project of the partners Sächsisches Textilforschungsinstitut e.V. (STFI), Chemnitz, Bundesanstalt für Arbeitsschutz und Arbeitsmedizin (BAuA), Berlin, IMA Materialforschung und Anwendungstechnik GmbH, Dresden and CFK Valley Stade Recycling GmbH & Co. KG, Stade. The project was funded as part of the Nano-Care4.0 programme.

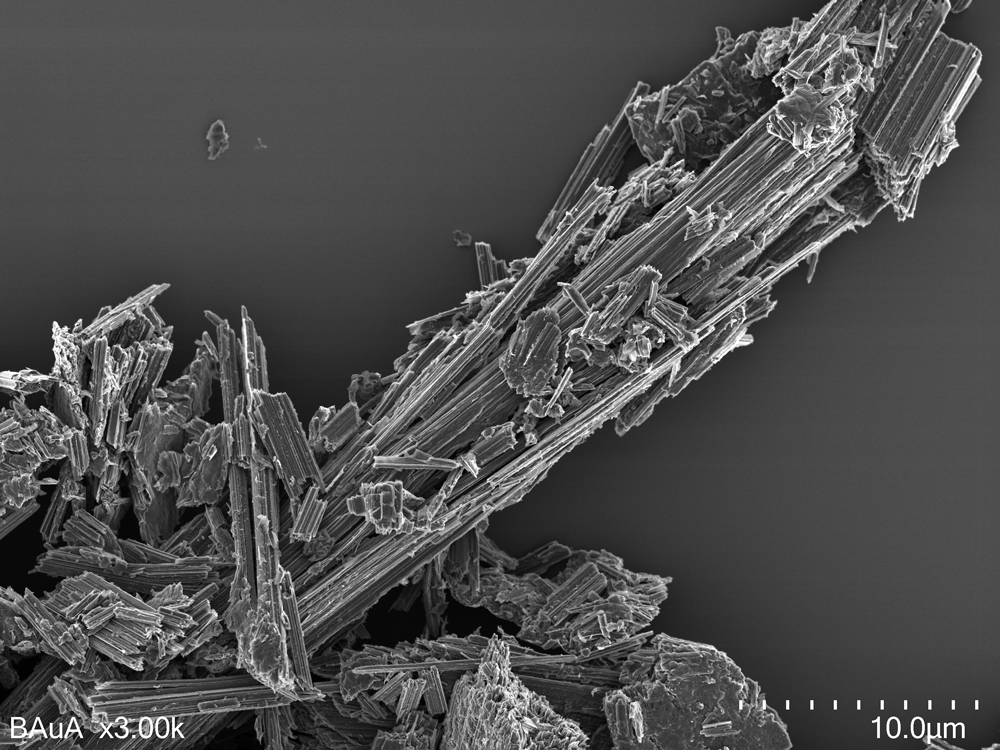

Scanning electron microscope image of carbon fibres and critical & health-relevant carbon fibre fragments © BAuA

For the fibres themselves and the polymer composites produced out of them, pre-investigations showed a partially strong tendency towards splintering at mechanical stress and mechanical processing. Up to now it is still unresolved how strong the potential is for releasing alveolar fragments within the entire life cycle of the fibres when stressed mechanically. The increasing importance of carbon fibres especially for lightweight and high-performance applications requires a deeper insight in dust and fibre releasing processes due to the high persistence of graphitic raw materials in biological systems. Joint cross-sectoral efforts of different disciplines such as safety research, materials science and product development are needed.

Based on the growing importance of carbon fibres (CF) for lightweight and high-performance applications, the aim of the project CarboBreak was to gain a deeper understanding of the fragmentation fracture behaviour of the fibres and to investigate the release processes of alveolar fragments from carbon fibres and CF reinforced composites. Possible connections between physical properties of the carbon fibres, the splinter fracture tendency and the formation of alveolar CF fragments were investigated.

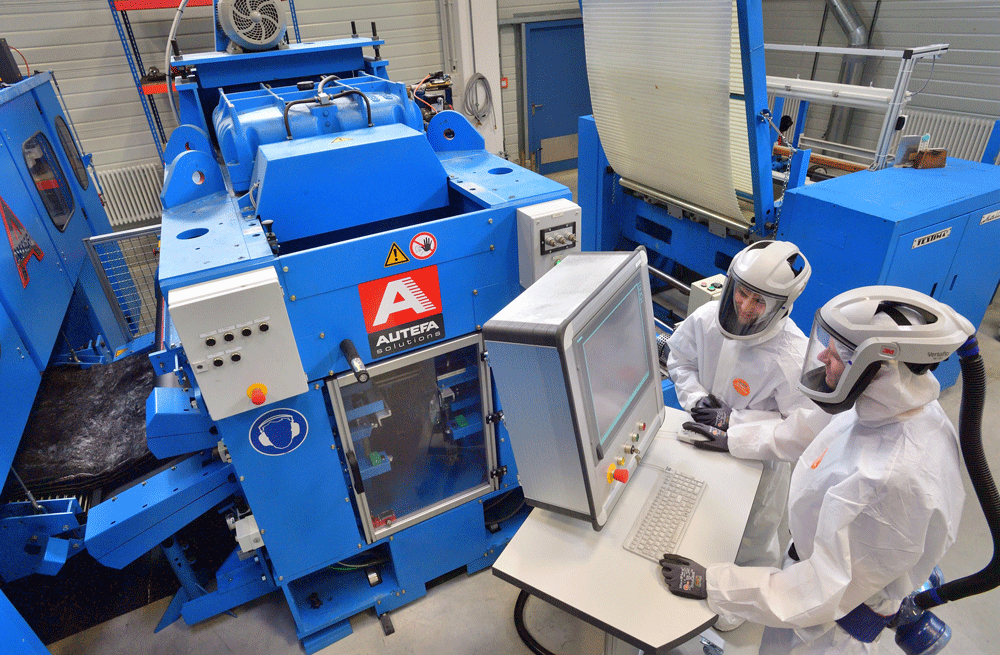

Occupational safety measures in the carbon fibre pilot plant of the STFI © Sächsisches Textilforschungsinstitut e.V.

Another focus of the project was the implementation of workplace measurements according to VDI 3492 and DGUV-Information 213-546. The measurements and sampling were implemented on site at the project partners’ premises and at industrial plants to ensure the link to practice. The project work covers the entire life cycle of carbon fibres, from the production of textile semi-finished products to the manufacture and processing of composites, recycling and reuse. The main results of the project are recommendations on work processes and personal safety as well as the identification of ideal or optimised process parameters during processing. The results of CarboBreak provide fundamental contributions for the development of application-safe material innovations.

- Project Flyer for Download (PDF, 4 MB )

- Project Poster (2021) “CarboBreak – Conditions and Mechanisms for releasing Alveolar Fibrous Carbon Fibre Fragments” (PDF, 816 KB )

MetalSafety

MetalSafety – Development of evaluation concepts for fibrous and granular metal compounds – bioavailability, toxicological efficacy profiles and comparative in vitro, ex vivo and in vivo studies

Metals and their compounds are ubiquitously present in our daily life, for example as components of stainless steel, catalysts, and pigments. Furthermore, metal compounds are being used in numerous innovative processes such as inks for 3D printing or as semiconductors in electronic engineering and medical devices. Apart from granular compounds of different particle sizes, the use of metal-based fibrous materials, so-called nanowires, in various products is increasing. However, many metals and their compounds reveal inflammatory and/or even carcinogenic potentials. Hereby, the toxicity often depends on the respective metal species; decisive factors are oxidation state and solubility and – in case of metal particles – their size (nano-/micro-scaled) as well as structure (granular or fibrous).

The aim of the scientific project MetalSafety is to design comparatively easy-to-use in vitro models for the toxicological evaluation and grouping of different metal-based compounds, which differ in their solubility and bioavailability. One main focus within this project lies on metal-based nanowires, since their toxicological potentials are hardly known. The toxicological profiles of these fibrous structures will be compared to the respective nano-scaled granular as well as water-soluble compounds.

For this purpose, an air-liquid interface (ALI) exposure system will be established to apply fibrous as well as granular structures on in vitro cellular models and to directly measure the deposited mass of the respective compound. The toxicological “finger prints” will be assessed using gene expression profiles, complemented by solubility, uptake and genotoxicity studies.

Afterwards, the results will be compared to complex ex vivo as well as in vivo studies and evaluated with regard to their predictability of the toxicological potential, the mode of action and the dose-response relationship. Species differences between human and rat with respect to toxicodynamic interactions will be obtained on the level of cell culture and precision cut lung slices (PCLS). The respective results will finally compared with data from in vivo studies in rats.

Altogether, the identification of relevant modes of actions by different metals and their compounds is an important prerequisite for a scientific-based derivation of workplace and environmental exposure limit values, including new, innovative metal fibres and granular metal compounds.