CarbonFibreCycle – Carbon fibres in circular economy – release behaviour and toxicity due to thermal and mechanical treatment

Results Report:

Carbon fibres (CF) and carbon fibre-reinforced plastics (CFRP) are indispensable as innovative materials in key technologies such as aircraft construction, the automotive sector and regenerative energy generation. The wide range of applications results from application-specific manufacturing and processing procedures, so that CFRP components can be specifically equipped with the required physical-chemical properties.

Since the production and processing of CF and CFRP is very energy- and cost-intensive, the aim is to recycle the fibres. Pyrolysis of CFRP components has established itself as the only commercially available technology to date. Often, this requires mechanical shredding of the components, which means that the available fibre length of recycled carbon fibres (rCF) is significantly less than that of the original fibre, and thus use in high-performance applications is no longer possible. Therefore, depending on the length, rCF are used as nonwovens and fillers in other materials or in consumer goods.

The disposal of the fibres at the end of their life cycle has also not yet been clarified, as the residence times of the fibres in both household waste incineration and hazardous waste incineration are not sufficient to completely thermally degrade the fibres.

In general, the increasing spread of CFRP products and the associated increase in production and processing steps as well as recycling and disposal processes can lead to the release of respirable biodegradable dusts and thus raise questions about the extent to which the fine dusts emitted in the process have an impact on humans and the environment.

The aim of the CFC project is to identify realistic release scenarios throughout the entire life cycle and the toxicological evaluation of the respirable dusts and fibres released. From this, recommendations for safe handling during production, processing, recycling and disposal of these materials are to be derived.

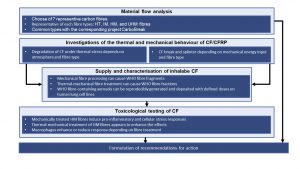

The CFC project is divided into six scientific work packages. In WP1, a material flow analysis will be carried out to identify relevant release scenarios of respirable dusts during mechanical or thermal stressing of CF/rCF/CFRP materials. Based on this, investigations will be carried out under thermal (WP2) and mechanical stress (WP3). In WP4, respirable test dusts from the mechanical and thermal exposure will be provided and characterised, which will be brought to the gas-liquid interface of human lung cells (ALI) in an airborne exposure system. In WP5, lung epithelial, macrophage and fibroblast cell cultures in mono- and coculture will be used for toxicological evaluation and investigation of respirable CF fragments. The investigations focus on cellular localisation, determination of cytotoxicity, gene expression analyses and the determination of inflammatory, fibrotic and genotoxic potential. The toxicological investigations are carried out with the ALI system, i.e. directly on the apical surface of the cells, in order to simulate lung-like conditions. The aim of AP6 is to assess hazards and risks based on the exposure limit values DNEL (derived no-effect level) and PNEC (predicted no-effect concentration). Recommendations for action are drawn up on this basis.

The inclusion of relevant actors from research, industry, associations and federal agencies in an advisory group ensures that the investigations are aligned with relevant boundary conditions. The Federal Institute for Occupational Safety and Health (BAA), the Federal Environment Agency (UBA), the Employer’s Liability Insurance Association for Raw Materials and the Chemical Industry (BG RCI), Carbon Composites (CCeV), the Reinforced Plastics Industry Association (AVK), CFK Valley Stade, the Interest Group of Thermal Waste Treatment Plants in Germany (ITAD), the German Chemical Industry Association (VCI), the company Pyrum Innovations and the University of Rostock are represented in the project advisory group.

Grant Number: BMBF - 03XP0195

Duration: 01.01.2019 - 31.12.2021 (extended to 30.06.2022)

Project Lead

Project Partners

https://www.itc.kit.edu/english/index.php

http://lmctox.iab.kit.edu/english/index.php

https://bip.ibcs.kit.edu/

https://www.teer.rwth-aachen.de/cms/~lksc/TEER/?lidx=1

https://www.ivw.uni-kl.de/en/home

Associated Partners

Publications

2023

- Friesen, A., S. Fritsch-Decker, S. Mulhopt, C. Quarz, J. Mahl, W. Baumann, M. Hauser, M. Wexler, C. Schlager, B. Gutmann, T. Krebs, A. K. Gossmann, F. Weis, M. Hufnagel, D. Stapf, A. Hartwig, and C. Weiss. "Comparing the Toxicological Responses of Pulmonary Air-Liquid Interface Models Upon Exposure to Differentially Treated Carbon Fibers." Int J Mol Sci 24, no. 3 (2023). doi:10.3390/ijms24031927.

2022

- Friesen, A., S. Fritsch-Decker, M. Hufnagel, S. Mulhopt, D. Stapf, C. Weiss, and A. Hartwig. "Gene Expression Profiling of Mono- and Co-Culture Models of the Respiratory Tract Exposed to Crystalline Quartz under Submerged and Air-Liquid Interface Conditions." Int J Mol Sci 23, no. 14 (2022). doi:10.3390/ijms23147773.

- Friesen, A., S. Fritsch-Decker, M. Hufnagel, S. Mulhopt, D. Stapf, A. Hartwig, and C. Weiss. "Comparing Alpha-Quartz-Induced Cytotoxicity and Interleukin-8 Release in Pulmonary Mono- and Co-Cultures Exposed under Submerged and Air-Liquid Interface Conditions." Int J Mol Sci 23, no. 12 (2022): 6412. https://doi.org/10.3390/ijms23126412.

2020

- Mülhopt S., Hauser M., Wexler M., Baumann W., Diebaté S., Fritsch-Decker S., Weiss C., Friesen A., Hufnagel M., Gutmann B., Schlager C., Krebs T., Goßmann A.-K., Weis F., Stapf D., Andrea H. (2020). Inhalable aerosols from carbon fibres. https://doi.org/10.5445/ir/1000125510

2022

- KIT Research to Business Blog (27.10.2022). Carbonfasern – Ein Werkstoff mit Gesundheitsrisiko? https://www.kit-technology.de/de/blog/carbonfasern-ein-werkstoff-mit-gesundheitsrisiko

- KIT Research to Business Blog (27.10.2022). Carbon fibers – A material with health risks? https://www.kit-technology.de/en/blog/carbon-fibers-a-material-with-health-risks

>

>