>

Spotlight April 2022: A new risk assessment of nanomaterials in 3D printing is needed

>

Spotlight April 2022: A new risk assessment of nanomaterials in 3D printing is needed

The use of nanomaterials in 3D printing has great potential. Due to the properties of nanoscale materials, many requirements can be implemented in 3D printing. However, these unique properties based on the size of the particles also lead to the need for new risk assessments. This is because if the nanoparticles are released in the printing process or subsequently from the finished product, they could pose a risk to humans and the environment. Future risk assessments of nanomaterials will therefore need to address not only the “non-nano” properties of the substances used, but also evaluate their size-based properties.

The review article by Taylor et al. presents the current state of the art regarding the use or emergence of nanomaterials in 3D printing. However, it also addresses the current safety precautions and regulations that must be followed when dealing with nanoparticles in 3D printing in various countries.

3D printing is used in many industries, including automotive and aircraft manufacturing. Alumina or zirconia are the most commonly used nanomaterials. The greatest risk to humans comes from nanoparticles that are released and subsequently inhaled or absorbed through the skin (see also “How can innovative materials (e.g.nanomaterials) enter the body or the environment?“). These are embedded in polymers (e.g., polyurethanes), metals (e.g., aluminum oxide), or biological materials (e.g., cellulose). Therefore, the nanomaterials are mainly released embedded in these carrier materials, but formation during the printing process for evaporation processes is also possible. So far, it is difficult to track the release of individual nanoparticles over the life cycle.

Future nanospecific regulations must therefore include analyses of the life cycle, the release potential, and an assessment of the hazard potential for humans and the environment. However, due to a lack of data on the number and form of nanomaterials released (free or bound) in 3D printing, many uncertainties remain about the exact risk. However, as knowledge about this will increase, regulations (e.g., on occupational health and safety) will also need to be more specific in the future.

Finally, the authors point out that early consultation of 3D printer manufacturers with authorities can lead to future regulations both meeting safety concerns and enabling practical implementation.

Original Publication:

Alicia A. Taylor, Elaine L. Freeman, Merel J.C. van der Ploeg, Regulatory developments and their impacts to the nano-industry: A case study for nano-additives in 3D printing. Ecotoxicology and Environmental Safety 2021, 207, 111458.

Weitere Spotlights

Spotlight April 2023: Recycling rare earths – bacteria assist in the circular economy

Rare earths are important components of wind turbines, catalytic converters, fibre optic cables and plasma screens. Since the 17 metals grouped under this term are indispensable for modern technologies, demand and costs are constantly rising. The occurrence of productive mining sites is limited and the production is often costly and environmentally harmful. The advantages of […]

Read moreSpotlight May 2021: Towards safe and sustainable innovation in nanotechnology: State-of-play for smart nanomaterials

The European Commission’s new Action Plan for a Circular Economy Green Deal, the new European Industrial Strategy as well as the Chemicals Strategy for Sustainability presented in October 2020 are ambitious plans to achieve a sustainable, fair and inclusive economy in the European Union. These strategies require that any new material or product must not […]

Read moreSpotlight May 2023: Dual energy – edible batteries

An Italian research group reports on edible batteries that supply electric current and can be digested as food, thus providing energy a second time. What sounds funny at first has a serious background, because in medicine, power sources are needed that could be transported through the digestive tract and possibly remain in the body unintentionally, […]

Read moreSpotlight June 2022: From small to clever – What does the future hold for the safety and sustainability of advanced materials?

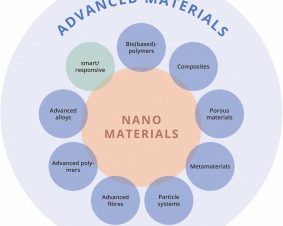

The smallest particles in materials research, nanoparticles, have occupied us intensively for more than 20 years to elucidate and further investigate their safety for humans and the environment. Now, however, the development is going from “small = nano” to “clever = advanced”, as discussed in a contribution by international scientists. Thereby, it is a great […]

Read more