>

Spotlight February 2023: New sustainable and promising method to give cotton textiles an antiviral and antibacterial finish

>

Spotlight February 2023: New sustainable and promising method to give cotton textiles an antiviral and antibacterial finish

Textiles have been the subject of research into functionalization for many years, especially also to repel bacteria and viruses. Since the development of nanotechnological processes, there have been many attempts to incorporate UV protection with nano-titanium dioxide, or to provide textiles with anti-bacterial properties with nanosilver (see cross-sectional text “Nanoparticles in Textiles”). But nanosilver has come under discussion because the particles are washed out of the textile after a few washing processes and the function is thus weakened or lost, but also the resource silver is relatively rare and the environment is polluted with the washed-out silver.

There is a recent study that uses a completely different element to functionalize cotton fibres and make them permanently anti-viral and anti-bacterial: copper! The process of functionalization is very sustainable because the solutions/lyes can be reused and only the copper itself has to be added for a new run. However, the amount of copper is relatively small, and the tests of the study showed that the functionalization is maintained even after up to 1000 washings, whereas the textile made of cotton reached its end of life after only 200 washings.

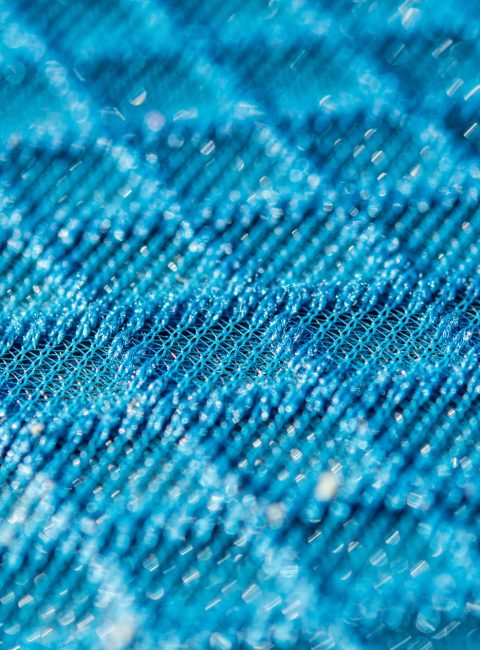

The process of functionalization is simple and upscalable, the distribution of copper ions in the fabric is very uniform (no particulate deposition, but ionic bonds). Tests with various viruses and bacteria have shown that this tissue is very efficient in killing these pathogens. Even mechanical stresses, such as crumpling or folding, do not reduce the lasting effect. The blue coloration by the copper has the additional advantage that especially for clinical staff the clothes do not have to be dyed separately, which also contributes to the sustainability of the product. Copper is much cheaper than silver, which makes it possible to provide certain textiles with simple, cost-saving, effective and long-lasting anti-viral and anti-bacterial properties without harming the environment.

Original publication:

Qian, J.; Dong, Q.; Chun, K.; Zhu, D.; Zhang, X.; Mao, Y.; Culver, J.N.; Tai, S.; German, J.R.; Dean, D.P., et al. Highly stable, antiviral, antibacterial cotton textiles via molecular engineering. Nat Nanotechnol 2022.

Weitere Spotlights

Spotlight May 2021: Towards safe and sustainable innovation in nanotechnology: State-of-play for smart nanomaterials

The European Commission’s new Action Plan for a Circular Economy Green Deal, the new European Industrial Strategy as well as the Chemicals Strategy for Sustainability presented in October 2020 are ambitious plans to achieve a sustainable, fair and inclusive economy in the European Union. These strategies require that any new material or product must not […]

Read moreSpotlight June 2021: Endotoxin – the reason for false-positive toxicity testing for advanced materials?

Advanced materials, but also nanomaterials are closely examined to determine whether they trigger biological effects that could be harmful to humans and the environment before they are used in products. This also includes such materials as titanium dioxide, which has been used in a wide variety of products for more than 50 years. A particularly […]

Read moreSpotlight July 2021: The Path to Digital Material Research – It is never too late to start

Machine Learning, Artificial Intelligence, Big Data…. Have you read these words lately? No, these are not just buzzwords. The digitalisation of science is an evolving topic that is gaining importance with each passing day. That is why this month we would like to introduce you to the article “Digital Transformation in Materials Science: A Paradigm […]

Read moreSpotlight November 2021: Safe Materials from Scratch – Safe-by-Design in Materials Research

Advances in the field of materials science continue to amaze us with nanoscale materials with extraordinary chemical, electrical, optical, and numerous other properties. However, some nanoscale materials have different toxicological profiles compared to the same bulk material. Since safety issues are usually addressed just before launching a product into the market, safety issues may be […]

Read more