>

Spotlight February 2023: New sustainable and promising method to give cotton textiles an antiviral and antibacterial finish

>

Spotlight February 2023: New sustainable and promising method to give cotton textiles an antiviral and antibacterial finish

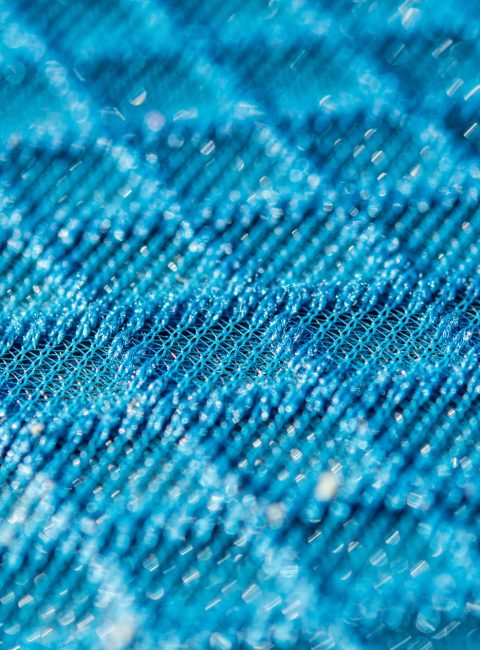

Textiles have been the subject of research into functionalization for many years, especially also to repel bacteria and viruses. Since the development of nanotechnological processes, there have been many attempts to incorporate UV protection with nano-titanium dioxide, or to provide textiles with anti-bacterial properties with nanosilver (see cross-sectional text “Nanoparticles in Textiles”). But nanosilver has come under discussion because the particles are washed out of the textile after a few washing processes and the function is thus weakened or lost, but also the resource silver is relatively rare and the environment is polluted with the washed-out silver.

There is a recent study that uses a completely different element to functionalize cotton fibres and make them permanently anti-viral and anti-bacterial: copper! The process of functionalization is very sustainable because the solutions/lyes can be reused and only the copper itself has to be added for a new run. However, the amount of copper is relatively small, and the tests of the study showed that the functionalization is maintained even after up to 1000 washings, whereas the textile made of cotton reached its end of life after only 200 washings.

The process of functionalization is simple and upscalable, the distribution of copper ions in the fabric is very uniform (no particulate deposition, but ionic bonds). Tests with various viruses and bacteria have shown that this tissue is very efficient in killing these pathogens. Even mechanical stresses, such as crumpling or folding, do not reduce the lasting effect. The blue coloration by the copper has the additional advantage that especially for clinical staff the clothes do not have to be dyed separately, which also contributes to the sustainability of the product. Copper is much cheaper than silver, which makes it possible to provide certain textiles with simple, cost-saving, effective and long-lasting anti-viral and anti-bacterial properties without harming the environment.

Original publication:

Qian, J.; Dong, Q.; Chun, K.; Zhu, D.; Zhang, X.; Mao, Y.; Culver, J.N.; Tai, S.; German, J.R.; Dean, D.P., et al. Highly stable, antiviral, antibacterial cotton textiles via molecular engineering. Nat Nanotechnol 2022.

Weitere Spotlights

Spotlight March 2023: How can photovoltaics be made safe and sustainable?

Conventional photovoltaic systems often have only low efficiency, i.e. only a fraction of the solar energy is converted into electrical energy and made usable. For this reason, research is being conducted into innovative materials that can significantly increase the energy yield and thus also enable more electrical energy to be generated from renewable sources. However, […]

Read moreSpotlight April 2021: Nanomaterials and Fake News – a commentary based on an example

In February 2021, the article “The invisible killer lurking in our consumer products” appeared, describing nanoparticles as a greater danger than Corona [1]. “The use of nanomaterials” would be “unregulated” and “nanomaterials are so small that they cannot be determined once they are part of a product”. So what is the truth of these statements? […]

Read moreSpotlight September: A methodology for the automatic evaluation of data quality and completeness of nanomaterials for risk assessment purposes

This paper describes a method for automatically assessing the quality and completeness of nanosafety data for the purpose of risk assessment. Steps to develop the methodology for assessing data completeness and the methodology for assessing quality are presented. The methodology is tailored to physicochemical and hazard (meta) data, but can also be configured with appropriate […]

Read moreSpotlight November 2022: Photonics in nature and bioinspired designs

Science has always taken nature as a model and imitated it. If you look at the field of photonics, i.e. the use of optical technologies for information processing, transmission or storage, the colorful examples in the animal and plant world are perfect basic drawers for technical applications. While colors in nature are used either for […]

Read more