>

Research

>

Research

The German Government’s Action Plan Nanotechnology 2020 provided an integrated concept for detecting the risks of nanomaterials for humans and the environment and for designing sustainable innovations.

This action plan focused on the further development of testing and measurement methods for risk characterisation, the support of research institutions and companies in the application-safe and environmentally compatible design of material innovations, the derivation of options for action for risk management and the further optimisation of risk communication.

This was supported by various higher federal authorities through a joint research strategy entitled “Nanomaterials and other innovative materials: application-safe and environmentally compatible”. The research projects were completed in 2023.

Spotlight Research

November 2023: Early Awareness and Action System for Advanced Materials (Early4AdMa)

Cluster-Meetings

Hier treffen sich die Partner der Projekte der BMBF Fördermaßnahme NanoCare4.0 Read more

Projects

2019-2023 NanoCare4.0 - Reliable material innovations - the new BMBF funding measure

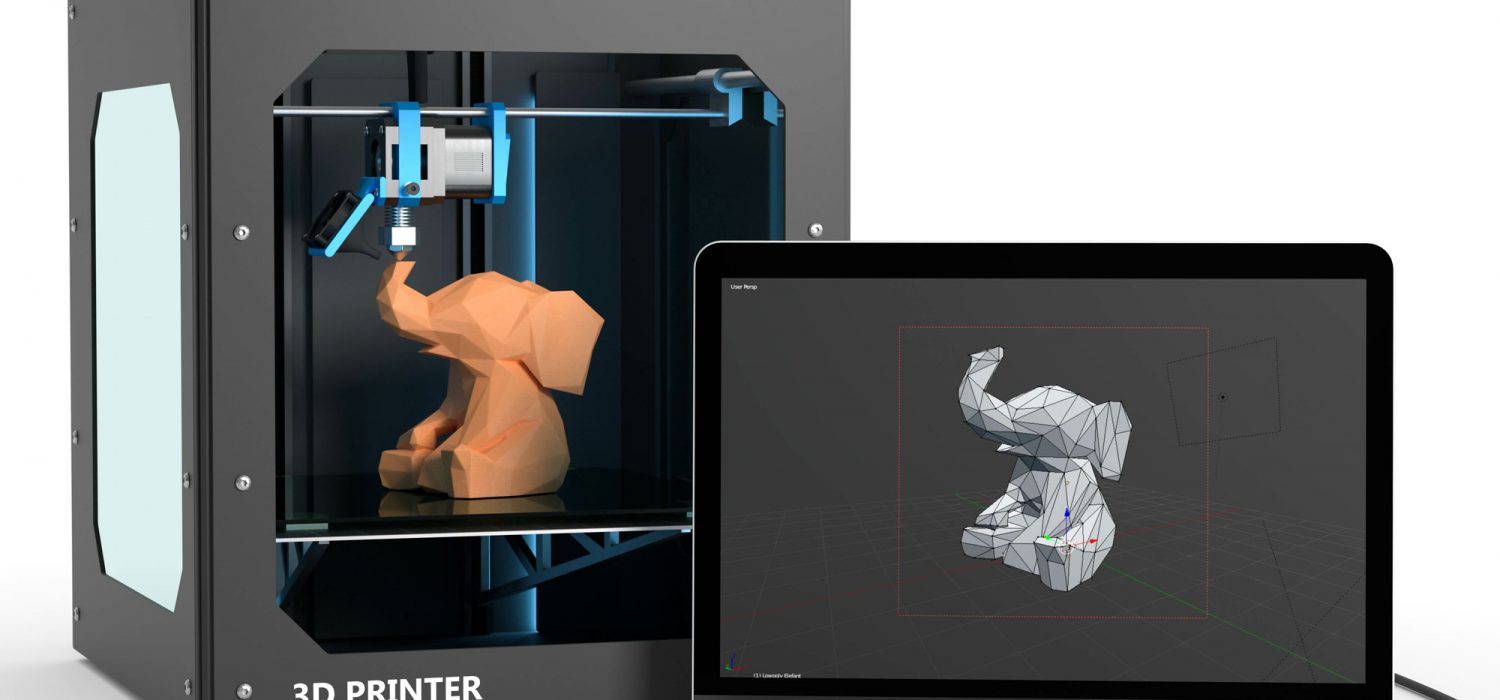

At present, the development and production of new materials are facing fundamental changes. New ways of material development include virtual material development with a computer-aided design, increasingly use digital data for modelling and simulation and support research into new material classes. Safety aspects must therefore be taken into account at an early stage in the development process and throughout the entire life cycle of the material. In order to meet these demands of industry and consumers, the new NanoCare4.0 funding measure is to investigate not only nanomaterials, but all innovative materials that are suspected of having harmful effects on the environment or health.

NanoINHAL

NanoINHAL - In-vitro test methods for airborne nanomaterials to investigate toxic potential and uptake after inhalation exposure using innovative organ-on-a-chip technologyRead more

InnoMat.Life

InnoMat.Life - Innovative Materials and new production processes: Safety along the Life Cycle and in industrial value chainsRead more

CarboBreak

CarboBreak - Prerequisites and mechanisms for the release of alveolar fibrous carbon fibre fragmentsRead more

MetalSafety

MetalSafety - Development of evaluation concepts for fibrous and granular metal compounds - bioavailability, toxicological efficacy profiles and comparative in vitro, ex vivo and in vivo studiesRead more

NanoCELL

NanoCELL - Comprehensive characterization and human toxicological assessment of nanocellulose along its life cycle for reliable risk assessment and safe use in environmentally friendly packaging materialsRead more

NanoBioQuant

NanoBioQuant - Quantification of nanomaterials in tissue for regulatory analysis and development of in vitro methodsRead more

CarbonFibreCycle

CarbonFibreCycle - Carbon fibres in circular economy – release behaviour and toxicity due to thermal and mechanical treatmentRead more

2014-2018: NanoCare 2

The funding initiative “NanoCare" as part of the framework program "From Material to Innovation" anchored in the new High-Tech Strategy aimed at innovation and growth of the industry in Germany. Based on the results and experiences of the previous action “NanoCare & NanoNature” (see below), the topic of safe handling of synthetic nanomaterials - research on the effects on humans and the environment was investigated in several project activities. A close cooperation between companies and research institutions in the university and non-university sector, the involvement of contributions from small and medium-sized enterprises (SMEs) and the exploitation of project results in Germany was of outstanding importance. From 2014-2018, a total of 11 projects was funded.

CaNTser

CaNTser - Investigating the toxic potential of carbon nanotubes after long-term inhalationRead more

ProCycle

ProCycle - Analysis and toxicological evaluation of dusts from recycling and recycling processes of nanocomposites and strategies for risk minimisationRead more

nanoGRAVUR

nanoGRAVUR : nanostructured materials – grouping for occupational health, consumer and environmental protection and risk mitigationRead more

nanoCOLT

nanoCOLT - Long-term effect of modified carbon black nanoparticles on healthy and damaged lungsRead more

NanoUmwelt

NanoUmwelt - Risk analysis of engineered nanomaterials in the environment: identification, quantification and analysis of the human- and ecotoxicological effectsRead more

InhalT-90

InhalT-90: 90 days inhalation testing with CeO2 in the rat and subsequent analysis of gene expression profiles for the early detection of toxic / carcinogenic effectsRead more

NanoSuppe

NANOSUPPE - Behaviour of engineered nanoparticles in the pathway wastewater - sewage sludge - plant using the examples TiO2, CeO2, MWCNT and quantum dotsRead more

Nanomobil

NANOMOBIL : Synthetic Silver Nanoparticles in the system Soil-Groundwater - mobility, effects on cohabitation and interaction between hydro-, pedo- and biosphereRead more

NanoBioDetect

NanoBioDetect - Nanoparticles in the tissue: detection, quantification and presentation of biological effect markersRead more

DaNa 2.0

DaNa 2.0 - Data and knowledge on Nanomaterials - Processing of socially relevant scientific factsRead more

2013 – 2019 ERA-Net SIINN – Safe Implementation of Innovative Nanoscience and Nanotechnology

FP7 ERA-NET SIINN - Safe Implementation of Innovative Nanoscience and Nanotechnology The ERA-NET SIINN Safe Implementation of Innovative Nanoscience and Nanotechnology promotes the safe and rapid transfer of European research results in nanoscience and nanotechnology (N&N) into industrial applications. National and regional resources will be virtually pooled to create a transnational programme of research. SIINN will bring together today's fragmented research activities on the potential risks of engineered nanomaterials for environment, human health, and safety. http://www.siinn.eu/

NANOHETER

NANOHETER - HETERoaggregation of manufactured NANOparticles with naturally occurring colloids in surface watersRead more

NanoSafeLeather

Nano Safe Leather - The effect on human health of silver-titanium dioxide nanomaterials -treated leathers for footwear industryRead more

NANOaers

NANOaers - Fate of aerosolized nanoparticles: the influence of surface active substances on lung deposition and respiratory effectsRead more

NanoWIR2ES

NanoWIR2ES - NanoWire Intelligent Re-design and Recycling for Environmental SafetyRead more

FATENANO

FATENANO - translocation, biological fate, stability and effective dose of engineered nanomaterials (ENM) for Nanosafety StudiesRead more

NANO-Transfer

NANO-Transfer - Transfer of carbon based nanomaterials (C-MNMs) into the aquatic environment: fate, effects, bioaccumulation, food web transfer, contaminant transport and use in the remediation of polluted watersRead more

ICONS

ICONS - Integrated Testing Strategy for mechanistic assessment of the respiratory toxicity of functionalized multiwalled carbon nanotubes (MWCNT)Read more

PLATOX

PLATOX -In vitro and in vivo investigations to generate validated toxicity data of graphene nanoplatelets vs a carbon black referenceRead more

NanoToxClass

NanoToxClass - Establishing nanomaterial grouping / classification strategies according to toxicity and biological effects for supporting risk assessmentRead more

FENOMENO

FENOMENO - Fate and effect of wastewater-born manufactured nanomaterials in aquatic ecosystemsRead more

nanOxiMet

nanOxiMet - Oxidant generating capacity as a metric to allow grouping of nanomaterials and prediction of human health effectsRead more

nanoIndEx

nanoIndEx - Assessment of Individual Exposure to manufactured nanomaterials by means of personal monitors and samplersRead more

2009-2014: NanoNature

NanoNature aimed at strengthening potential nanomaterial market segments in the environmental field and at enhancing the export of environmentally relevant materials and technologies. In addition, systematic analyses were carried out and adapted measuring methods have been developed to assess the release, distribution, fate, and effect of synthetic nanoparticles and nanomaterials in the environment.

Nano-SCR

kitNano-SCR - Development of nanoscale SCR catalysts for combined NOx and soot reduction in diesel enginesRead more

NanoMembrane

NanoMembrane - Nanoporous ceramic membranes for use in sustainable closed-cycle water- and solvent-saving methodsRead more

NanoKiesel

NanoKiesel - Nanoscale silica slurry - Technology developments on nanoscale silica slurry use in mineral building materials with the aim of improving material propertiesRead more

UMSICHT

UMSICHT - Assessment of the environmental hazards of silver nanomaterials: From chemical particles to technical productsRead more

NanoPurification

NanoPurification - Development of advanced materials and methods for water and sewage treatment by means of functional nanocompositesRead more

NanoPharm

NanoPHARM - New photocatalytically active composite materials for elimination of pharmaceutical residuesRead more

NADINE

NADINE - Nanomodified diamond electrodes for inline disinfection in different fields of applicationRead more

Fe-NANOSIT

Fe-NANOSIT - Iron-based nanoparticles and nanocomposite structures for removal of contaminantsfrom groundwater and sewageRead more

NanoFlow

NANOFLOW - Mobility of synthetic nanoparticles in water-saturated and variably water-saturated subsoilsRead more

NanoSan

NanoSAN - A nanotechnological clean up method – In situ use of iron oxide nanoparticles for elimination of harmful substances from abandoned polluted areasRead more

2009-2014 NanoCare

NanoCare intended to further investigate systematically the human-toxicological effects and interactions occurring during the production, processing, and application of synthetic nanomaterials. External and internal exposures have been be quantified, material-specific toxicity parameters were determined, and mechanisms of action were identified to detect and predict possible toxic effects on humans along the life cycle of the investigated nanomaterials.

Nanosilberpartikel

Nanosilver particles - Mechanisms of action and investigation of their possible interaction with tissues, cells and molecules. Definition of their relevant potential for intoleranceRead more

NanoMed

NanoMED - Toxicological characterisation of nanomaterials for the diagnostic imaging in medicineRead more

NanoExpo

NanoExpo - Nanobalance detectors for individual-related measure-ments of nanoparticle exposuresRead more

DaNa

DaNa - Acquisition, evaluation and public-oriented presentation of society-relevant data and findings relating to nanomaterialsRead more

CarboTox

CarboTox - Development of screening methods to analyse cancerogenous potential of carbon nano tubesRead more

CarbonBlack

CarbonBlack - Prediction of the human-toxicological effect of synthetic carbon black nanoparticlesRead more

2008-2014: Inno.CNT - Innovation Alliance Carbon Nanotubes

In a scientific alliance with more than 90 renowned partners from research and industry, the Inno.CNT initiative is systematically advancing the development of carbon nanotubes (CNT). The tiny carbon nanotubes have the potential to open up brand-new dimensions in materials technology and bring a unique quality to numerous products and applications.

Inno.CNT – CarboLifeCycle

CarboLifeCycle - Innovation Alliance Carbon Nanotubes: Innovation for industry and societyRead more

Inno.CNT – CarboAir

CarboAir - Innovation Alliance Carbon Nanotubes: Innovation for industry and societyRead more

Inno.CNT – CarboSafe

CarboSafe - Innovation Alliance Carbon Nanotubes: Innovation for industry and societyRead more

2006-2009: NanoCare-Cluster: NanoCare; INOS; Tracer

INOS

INOS - Identification and Assessment of the Effects of Engineered NanOparticleS on Human and Environmental HealthRead more